services

3D MODELS

• Robust parametric part modeling and modification.

• Can begin with a mechanical need, concept, napkin sketch or careful modification according to strict design control.

• Advanced CAD needs like surface, thread, gear, and sheet metal modeling.

• Reverse engineering from CAD export, PDF, scan data, or physical part.

• Assembly design, modification, and exploding 3D models.

• PDM set-up, clean up, and custom integrations.

• Custom simulations and CAD automations.

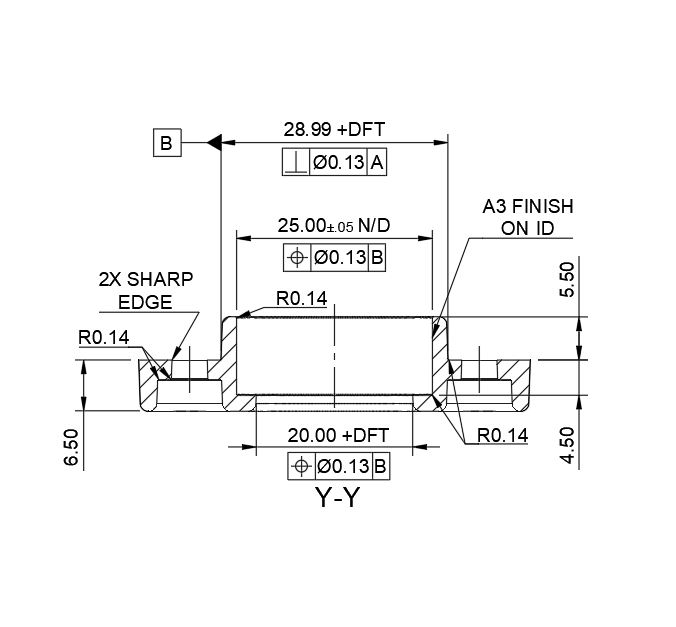

2D DRAWINGS

• Expert 2D drawing creation and modification.

• Advanced drawing needs like BOM’s, exploded diagrams.

• Creating drawings for off-the-shelf components.

• GD&T review.

• Custom title blocks.

• Establishing drawing standards and best practices.

• Establishing design control processes.

• Vendor negotiation.

ANALYSIS

• Draft, undercut, and wall thickness analysis for well- made injection molded parts.

• Tolerance stack-up analysis for setting smart tolerances for parts in context of the assembly, design verification, or root cause analysis for assembly issues.

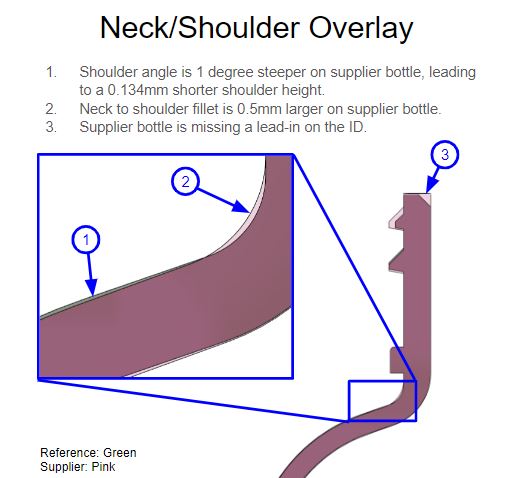

• Overlay analysis. Useful for understanding under-documented design changes and for validating a manufacturer’s model..

• Visually communicating design function or concepts in 3D models or 2D graphics for design reviews, stakeholders, or customers.